- The Faculty

- Academic

- Postgraduate

- Directorates

- Self-Evaluation

- Transparency

- Continuing Education

The laboratories of FPUNE aim to provide high-quality and relevant education in knowledge, skills, and human values. Their success is based on a solid and committed teamwork for sustainable development, offering quality service in attending to students and professors during practical and research activities, thereby contributing to the development of theoretical and practical skills in the students education and acquiring attitudes that reflect a common sense towards professional development.

Laboratories are of great importance to students, as they carry out practical exercises that aim to link the theory seen in the classroom with the practice of the profession in real life, i.e., to verify that the phenomena seen in a theoretical way happen in reality.

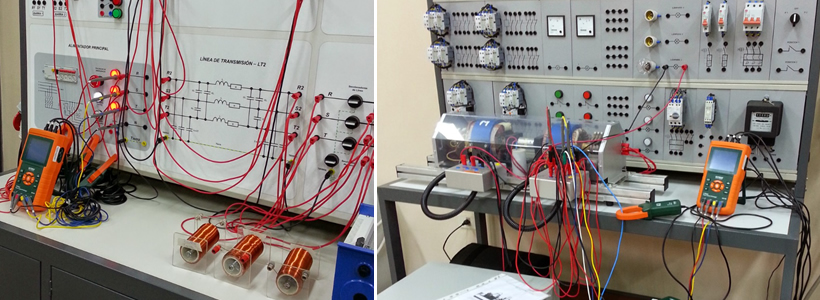

This laboratory includes a set of equipment aimed at illustrating a wide range of applications in electrical engineering. Depending on the level of knowledge, students can carry out introductory as well as more complex and specific experiments. The laboratory is intended for the study of the principles of electricity, so that students can experiment with the physical principles observed in both linear and non-linear electrical circuits. The activities are carried out by the students autonomously or guided by a teacher.

Some of the activities promoted by this laboratory are:

The main objective of this Laboratory is to allow the design, construction, and testing of electronic circuits and devices based on analog and digital electronics. Students interact with circuits of various complexities, starting from basic circuits with discrete electronic components, passing through analog and digital integrated circuits.

Some of the practices carried out in this laboratory are:

ingles

ingles This laboratory carries out industrial automation and control practices with the aim of providing our students with a broad vision of industrial automation technologies. The laboratory practices cover the pyramid of industrial automation. It covers topics such as protection and control of electric motors, industrial sensors, programming of programmable logic controllers (PLCs), control of pneumatic drives, supervision applications, control and data acquisition, and industrial communications.

Some of the practices carried out in this laboratory are:

p class="text-justify">This laboratory work allows students to understand the operation and specific characteristics of the fundamental electromechanical energy conversion machines: transformers, AC and DC rotating machines. The behavior of full-scale machines is studied based on their parameters and as part of a system.

p class="text-justify">This laboratory work allows students to understand the operation and specific characteristics of the fundamental electromechanical energy conversion machines: transformers, AC and DC rotating machines. The behavior of full-scale machines is studied based on their parameters and as part of a system. Some of the activities promoted by this laboratory are:

The computer labs at FPUNE are equipped with computers, software, and connectivity resources that are appropriate in quantity for the number of students and requirements of the study programs for various subjects. This enables sessions to be conducted in suitable conditions for the teaching-learning process.

Currently, there are five (5) computer labs with one hundred (100) computers, which are used for specific subjects in the four undergraduate programs and postgraduate programs, ensuring one student per computer according to the assigned schedule.

These labs implement mechanisms for administration and control that allow for the concentration, optimization, and regulation of Internet use, file sharing, and other services according to usage needs. All labs have the required safety elements, such as biosecurity controls, electrical protection, fire prevention systems, and others.

The Hardware and Networks Laboratories of the Faculty of Engineering, unlike its other computer laboratories that are generally designed to perform office activities and application development through programming tools, are intended for the application of knowledge acquired by students who have taken courses related to Computer Architecture or Computer Networks. Since 2011, it has been supporting specific training courses for these areas, in addition to guiding students who develop final degree projects related to these areas.

Some of the activities promoted by this laboratory are:

Physics, one of the pillars of Technology, is a science that deals with understanding the most diverse observable phenomena of the Universe. "Studying physics" is an activity that therefore requires not only reading appropriate texts, but also observing, manipulating, and experimenting with phenomena. To understand the meaning of concepts and the scope of the laws and theories of physics, all the activity carried out in physics laboratories is essential.

In addition to observation and experimentation, the physics laboratory promotes learning observation and measurement techniques, and the correct use of corresponding instruments and equipment. For this, our laboratory has a set of practices with their corresponding work guides (of our own elaboration). In addition, planning and execution of projects (starting from the 2nd semester) are carried out, which promote exercise in innovation and self-management, which are extensively applied in all branches of science and technology.

In summary, the physics laboratory is a powerful didactic resource in the learning of every scientific-technological career, being therefore essential for engineering training.

Some of the practices and projects carried out by this laboratory are:

Mechanics

Fluids, Heat, and Waves

Electricity and Magnetism

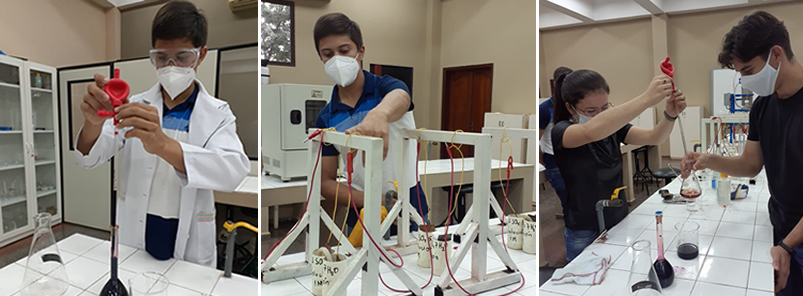

The realization of laboratory experiments is a fundamental element in the teaching/learning process of Chemistry. Laboratory practices can help the student, in addition to developing basic skills in the use of experimental chemistry tools and data processing, to handle basic concepts, understand the role of direct observation in Chemistry and distinguish between the inferences made from theory and those made from practice; to highlight the process: observation of the phenomenon - obtaining experimental data - analysis of results - conclusions.

The practices in this laboratory aim to: Provide a broad and general experimental training, initiating students in laboratory work and serve as a space for "visualization" of what is studied in "theory classes".

Some of the experiments and projects carried out by this laboratory are:

This laboratory significantly contributes to the training of electrical engineering professionals, allowing for better theoretical and practical knowledge related to overhead distribution networks. In addition, it allows students to design the construction of new lines, as well as the maintenance of existing networks, applying assembly practices, fault detection, and repair. It also enables the analysis of different components and the mechanical and electrical elements that make up a Low Voltage (L.V.) and Medium Voltage (M.V.) overhead power distribution network according to their functions and properties.

Among the activities developed and topics focused on in this laboratory, we can mention the following:

chanel.villalba@fpune.edu.py

Int. 221

marcos_rivarola@fpune.edu.py

Int. 150

hugo.zaracho@fpune.edu.py

Int. 221

arnaldo.portilloanzoategui@fpune.edu.py

Int. 221

gaspar.rodriguez@fpune.edu.py

Int. 122

aldoariel@fpune.edu.py

Int. 150

patricia.guillen@fpune.edu.py

Int. 123

Int. 236

Int. 236

Int. 236

Int. 221